| Product name |

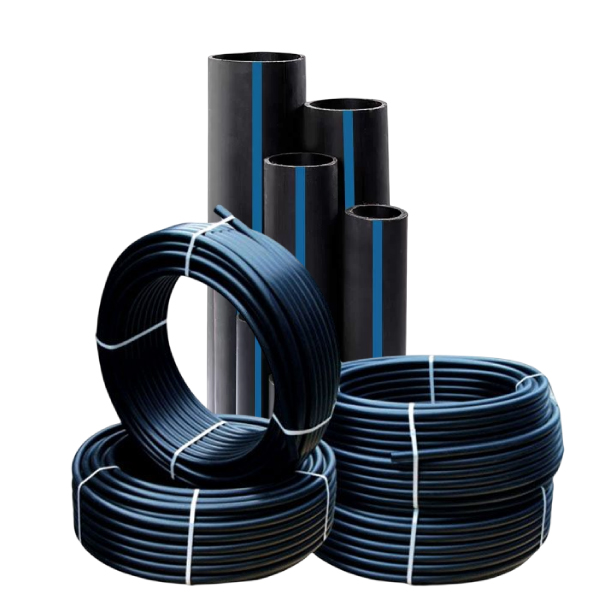

High Density Polyethylene (HDPE) Pipe for Underground Cable |

Production Capacity |

200*40ft containers/month |

| Brand |

Abbonite Plastics Pvt. Ltd. HDPE Pipe(or OEM) |

Sample |

Free sample available |

| Dia. ranges |

DN20-2000mm(1/2 inch-80 inch) |

Delivery time |

5-10 days, depending on the quantity |

| Pressure Class |

SDR17 to SDR6; PN10 to PN32 |

Test/Inspection |

National standard laboratory, Pre-delivery inspection |

| Standards |

ISO 4437, ASTM D3035, ASTM D2513, EN 1555, GB/T 15558, AS/NZS 4130, GOST 18599 |

Certificates |

ISO9001, ISO14001, ISO45001, CE... |

| Raw material |

PE80, PE100, PE4710, PE3608, PE100RC... |

Management |

effective 8S management system |

| Color |

black with blue stripes, orange or other colors you want |

Warranty |

60 years with normal use |

| Packing |

5.8m or 11.8m/length, 100-200m/roll, for pipe. Cartons or bags, for fittings(customizable)

|

Quality |

QA & QC system, Ensure traceability of each process |

| Application |

Power, Site lighting, Signal and control, Renewable energy... |

Employees |

More than 200 |

| Matching products |

Butt fusion hdpe Pipe fittings, Socket fusion hdpe pipe fittings, Electrofusion hdpe pipe

fittings, Compression fittings, Welding machines and tools, etc. |

Service |

Research, Design, Sales, Solution providing, Test, Manufacture, Aftersales service |